PREVENTIVE & PREDICTIVE MAINTENANCE

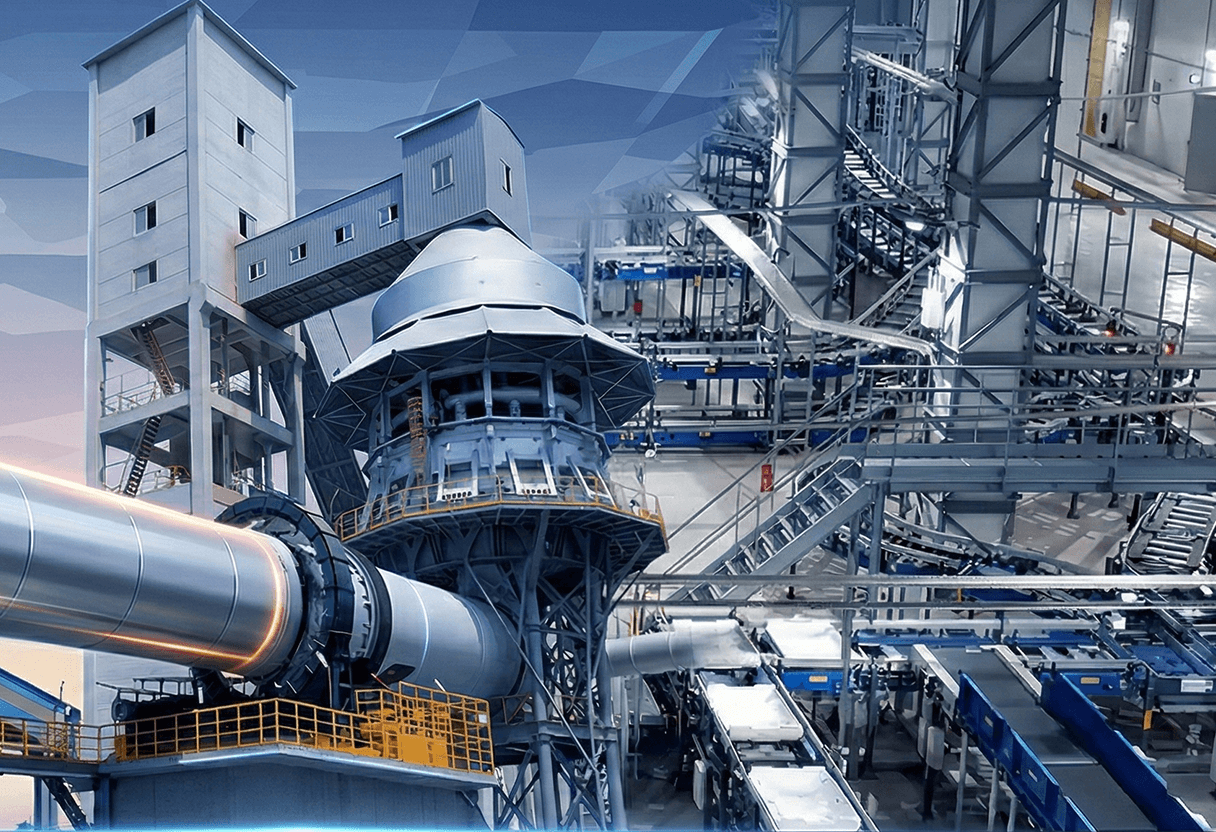

Preventive & Predictive Maintenance is the foundation of industrial reliability engineering. Unlike corrective maintenance, which reacts to equipment failure, preventive and predictive methodologies eliminate failure before it emerges—extending asset life, reducing operational expenditure and preserving system safety. This discipline is particularly vital for chemical plants, where unplanned downtime can lead to hazardous process instability, and water treatment plants, where continuous pump and filtration reliability protects municipal infrastructure and public well-being.

In chemical processing environments, where assets operate under extreme thermal, corrosive and pressure-intensive conditions, maintenance must be scientifically structured and timeline-driven. Pumps, heat exchangers, cooling towers, centrifuges, agitators, boilers, reactors, scrubbers, dosing systems and high-pressure pipelines demand periodic stress testing, lubrication analysis, vibration analytics and thermal behaviour trending to remain within safe process limits. Precision maintenance mitigates polymerisation fouling, corrosion, material fatigue and seal deterioration—ensuring uninterrupted reaction cycles and zero deviation in batch quality.

In water treatment ecosystems, continuous operation is non-negotiable. Chlorination units, blowers, booster pumps, membrane filtration skids, sludge presses and disinfection systems depend on uninterrupted mechanical and electrical uptime to maintain safe potable water parameters. Predictive maintenance plays a decisive role through motor efficiency analytics, pump curve monitoring, remote I/O diagnostics, chemical dosing accuracy checks, drive temperature tracking and real-time SCADA alerts. When the maintenance strategy is properly engineered, the plant protects its service continuity, asset health and compliance with environmental and public safety standards.

The discipline integrates industrial analytics, IoT-enabled monitoring, condition-based scheduling, reliability-centred engineering and lifecycle asset management. It elevates maintenance from a cost-driven activity to a business-critical investment in uptime, stability and long-term lifecycle value.

Preventive Maintenance Programs

“Planned Interventions for Guaranteed Equipment Service Life”

Preventive maintenance follows defined periodic schedules based on OEM standards, operating hours and load profiles. Activities include lubrication cycles, torque recalibration, temperature profiling, bearing replacement, seal renewal, alignment correction, heat exchanger descaling and pressure control element refurbishment. In chemical plants, this ensures safe reactor operation and injection skid reliability; in water treatment plants, it preserves mechanical efficiency in high-circulation pump systems and blowers. The result is predictable equipment behaviour and longer component lifespan.

Predictive Data-Driven Maintenance

“Failure Prevention Through Real-Time Performance Intelligence”

Predictive maintenance identifies early-stage failure patterns through continuous asset performance analytics rather than time-based scheduling. Using vibration spectrum analysis, ultrasonic leak detection, motor current signature analysis (MCSA), thermal imaging, digital pump curve comparison and PLC/SCADA event history trending, emerging anomalies are detected long before they impact production. This enables proactive intervention and reduces downtime by preventing critical breakdown events.

Condition-Based Monitoring Programs

“Proactive Reliability Through Continuous Diagnostic Analysis”

Condition-based maintenance builds a live health profile of rotating and static equipment. Sensors monitor temperature gradients, hydraulic pressure shifts, load fluctuations, axial displacement, noise signature variance and lubrication film integrity. Instead of repairing after breakdown, the system triggers intervention only when performance deviates from baseline thresholds. This ensures maximum equipment usage while maintaining full operational safety margins.

Annual Maintenance Contracts (AMCs)

“End-to-End Equipment Protection with Guaranteed Uptime”

AMCs unify preventive and predictive strategies under long-term reliability governance. Scope of work includes manpower deployment, spare lifecycle management, emergency support, inventory optimisation, failure-rate analytics, statutory inspections, energy efficiency improvement and SLA-driven performance reporting. For chemical and water treatment facilities, AMCs ensure uninterrupted functionality of core infrastructure—ensuring uptime commitments, cost predictability and full asset lifecycle protection.