MECHANICAL MAINTENANCE

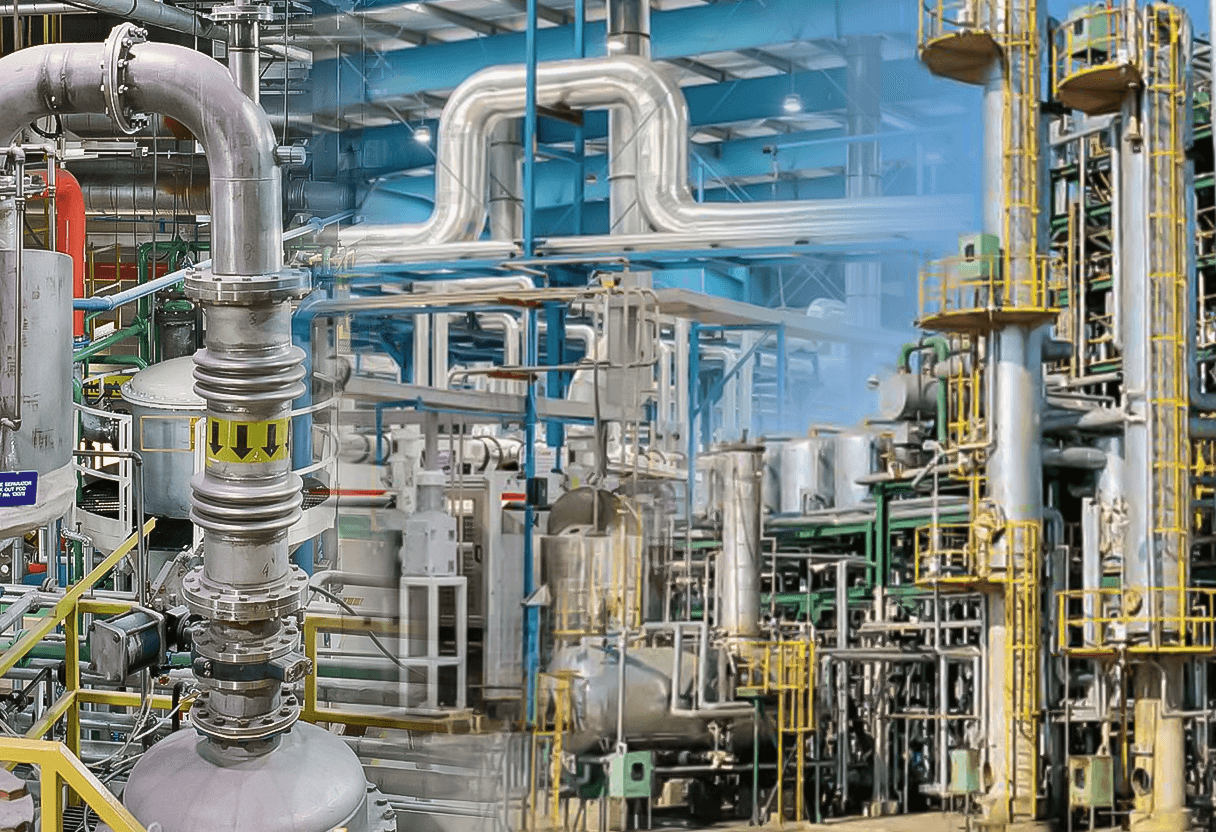

Mechanical systems form the backbone of every industrial and energy-producing facility. From the rotating equipment of oil refineries, to high-torque machinery inside power stations, to precision assembly systems across heavy manufacturing plants, uninterrupted mechanical performance is non-negotiable. Our Mechanical Maintenance division ensures reliability across critical equipment cycles by combining engineering accuracy, advanced fault diagnostics and disciplined shutdown planning. Whether it’s scheduled preventive maintenance or emergency breakdown support, we restore full mechanical integrity with zero compromise on safety or productivity.

We support on-ground, high-risk environments where machinery operates under extreme loads and fluctuating temperatures. By deeply integrating field inspection, vibration analytics, lubrication science, alignment calibration and component lifecycle tracking, we drastically minimize mechanical deterioration and improve longevity. Our multidisciplinary teams maintain total operational uptime, reduce energy wastage and stabilize production throughput—especially in facilities where equipment unavailability leads to massive opportunity losses.

Our Mechanical Maintenance operations are fully adaptable for complex industrial assets such as furnaces, boilers, compressors, turbines, heat exchangers, gearboxes, pumps, overhead cranes, conveyor systems, chillers and high-capacity rotating units. Working within live industrial zones and high-temperature environments, we follow stringent OEM standards, API guidelines and international safety frameworks. The end result is mechanical equipment that performs optimally at scale—safely, efficiently and continuously.

Factory Mechanical Maintenance

“Precision Engineering for High-Volume Industrial Machinery”

Factories operate on cycle-time accuracy, where every second impacts production yield. Our Factory Mechanical Maintenance service is engineered for high-volume manufacturing environments where repetitive motion, automated assembly systems and continuous-duty equipment demand precise mechanical balance. We conduct real-time wear analysis on bearings, shafts, couplings and hydraulic components to prevent micro-friction failures that lead to catastrophic downtime. By calibrating throughput-critical machinery—including conveyor lines, robotic cells, pneumatic presses and forming equipment—we maintain the mechanical harmony required for high-speed and high-accuracy factory operations.

Oil & Gas Mechanical Maintenance

“Asset Integrity and Zero-Downtime Field Operations”

Oil & gas assets run under extreme stress conditions, involving high pressure, corrosive fluids and 24/7 continuous duty. Our maintenance solutions protect rotating and static assets including reciprocating pumps, API-certified valves, turbine drivers, flare systems, heat exchangers and high-pressure piping assemblies. We deploy shutdown teams for refineries, petrochemical plants, FPSO platforms and distribution terminals with a single mission: zero unplanned downtime. By integrating corrosion-control protocols, metallurgy-based failure diagnostics and certified torque-tensioning methods, we protect the structural and functional life of energy-critical mechanical equipment.

Industrial Plant Mechanical Maintenance

“Maximizing Lifecycles of Rotating & Static Equipment Under Heavy Load”

Industrial plants involve rugged operating cycles where heavy-load machinery carries massive mechanical demand over prolonged durations. Our maintenance programs focus on the mechanical endurance of key systems such as compressors, industrial turbines, cooling towers, boilers, mills and crushing systems. We apply laser alignment, thermal mapping and structural vibration correction to maintain rotational balance and eliminate hidden high-stress points. This results in prolonged equipment life, high efficiency, reduced heat losses and increased productivity—even in plants where mechanical load is exponentially high across multi-shift production.

General Mechanical Maintenance

“Optimizing Multi-System Building Performance and Longevity”

For commercial and mixed-use facilities, we maintain complete mechanical ecosystems ranging from HVAC systems to hydraulic lifting equipment, firefighting pumps, chilled water systems and generators. Our general maintenance teams focus on proactive intervention—ensuring that temperature control, ventilation, fluid movement and emergency systems operate without disruption. By optimizing mechanical efficiencies and calibrating load-bearing equipment, building performance significantly improves while safety standards are fully maintained. The result is stable infrastructure life, reduced power consumption and smoother 24/7 operational environments.